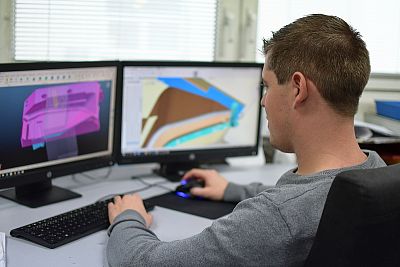

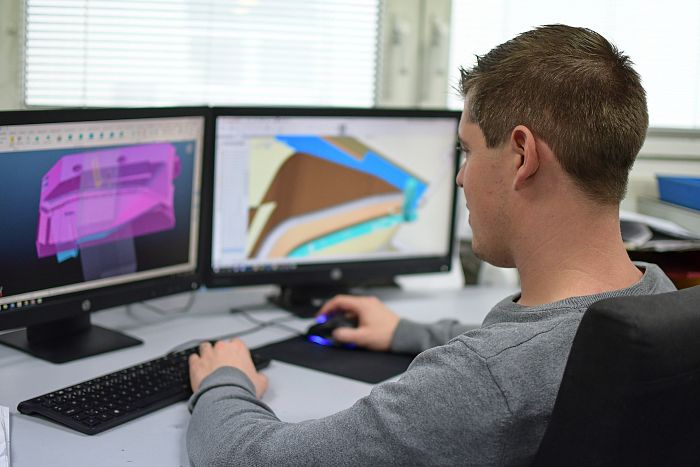

Constructing all project tasks takes place in a fully 3D environment, with the ability to produce outputs in all commonly used 3D and 2D formats. The FMEA method is applied in the development of structural units using the Palstat CAQ programs.

The goal of the Department of Design is to prepare the construction groundwork necessary for the implementation of entire plastic part production projects, including their assembly.

- preparation and development of plastic products - production of 2D and 3D documentation

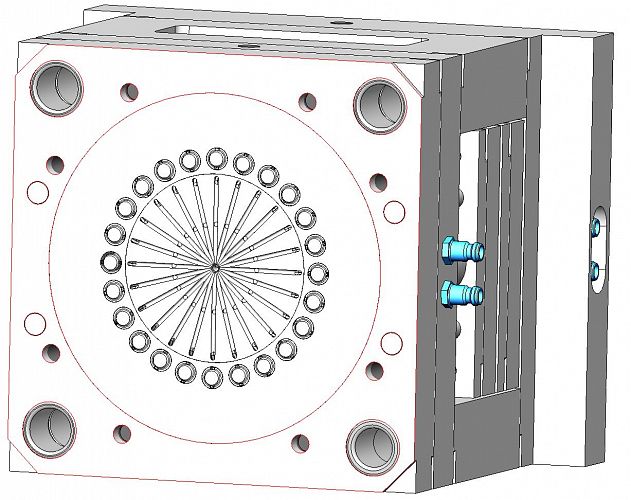

- tool development - injection mold design including electrode preparation

- development of measuring devices needed for measurement in pre-series and serial production

- development of assembly fixtures

- development of the products needed for coating technology

- development of equipment necessary for automation of production sites